Applications of BIM in Tunneling Projects

Building Information Modeling (BIM) has become a transformative tool in the architecture, engineering, and construction (AEC) industries. Its applications in tunneling projects, in particular, are vast and revolutionary. BIM’s integration into tunneling provides numerous benefits, from enhanced design accuracy and collaboration to improved project management and risk mitigation.

This article delves into the multifaceted applications of BIM in tunneling projects, highlighting its advantages and providing insights into its potential future developments.

Enhancing Design Accuracy and Visualization

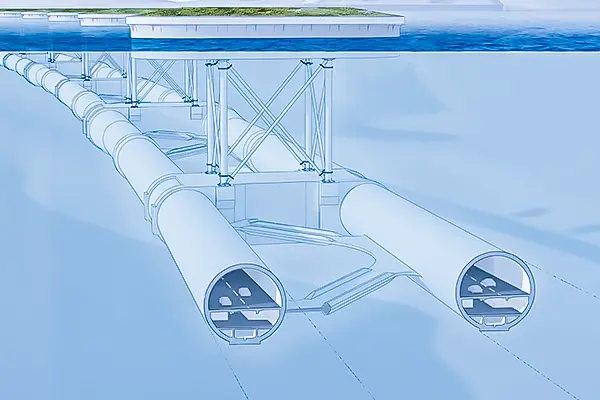

One of the primary benefits of BIM in tunneling projects is its ability to enhance design accuracy. Tunneling is a complex process that requires precise planning and execution. BIM allows engineers to create detailed 3D models of tunnels, incorporating various geological and structural data. These models provide a comprehensive visualization of the tunnel design, enabling stakeholders to better understand the project before construction begins.

BIM’s visualization capabilities are not limited to 3D models. It can also generate 4D and 5D models that incorporate time (scheduling) and cost data, respectively. This holistic approach allows for more effective planning and resource allocation, ensuring that all aspects of the project are considered. Furthermore, BIM models can simulate various scenarios, such as the impact of different tunneling methods or the potential effects of geological changes, aiding in decision-making and risk assessment.

Facilitating Collaboration and Communication

BIM’s collaborative nature is another significant advantage in tunneling projects. Traditional project management methods often involve disparate systems and siloed information, leading to communication breakdowns and errors. BIM, however, centralizes project data in a single platform, accessible to all stakeholders. This transparency fosters better communication and collaboration among engineers, architects, contractors, and clients.

Real-time updates to the BIM model ensure that all parties are working with the most current information, reducing the likelihood of errors and rework. Additionally, BIM’s ability to integrate data from various sources, such as geological surveys, environmental impact assessments, and utility records, provides a comprehensive view of the project. This integration facilitates better coordination among teams and ensures that potential conflicts are identified and resolved early in the project lifecycle.

Improving Project Management and Efficiency

BIM significantly enhances project management in tunneling projects. The detailed models and integrated data provide project managers with a clear overview of the project, allowing for more accurate scheduling, budgeting, and resource allocation. BIM’s ability to track project progress in real-time enables managers to identify potential issues early and take corrective action, minimizing delays and cost overruns.

Furthermore, BIM’s integration with other project management tools, such as construction management software and enterprise resource planning (ERP) systems, streamlines workflows and improves efficiency. Automated processes, such as clash detection and quantity takeoffs, reduce the time and effort required for manual calculations and inspections. This automation not only saves time but also enhances accuracy, further reducing the risk of errors and rework.

Learn more: BIM for project managers

Enhancing Risk Management and Safety

Risk management is a critical aspect of tunneling projects, given the inherent uncertainties and challenges associated with underground construction. BIM plays a crucial role in identifying and mitigating risks throughout the project lifecycle. By integrating geological and geotechnical data into the BIM model, engineers can better understand the subsurface conditions and predict potential issues, such as ground instability or water ingress.

BIM’s simulation capabilities allow for the analysis of different construction methods and scenarios, helping to identify the most effective and least risky approaches. Additionally, BIM can be used to develop detailed safety plans and procedures, incorporating information on site conditions, equipment, and personnel. These plans can be visualized and communicated to all stakeholders, ensuring that safety protocols are understood and followed.

During construction, BIM continues to support risk management by providing real-time monitoring and analysis of the project. Sensors and monitoring equipment can be integrated with the BIM model to track key parameters, such as ground movement, structural integrity, and environmental conditions. This data allows for proactive decision-making and immediate response to potential issues, enhancing overall safety and reducing the risk of accidents.

Supporting Maintenance and Operations

The benefits of BIM extend beyond the construction phase, supporting the maintenance and operation of tunnels throughout their lifecycle. The detailed BIM model serves as a comprehensive digital record of the tunnel, capturing all relevant data, including design specifications, construction methods, and material properties. This information is invaluable for maintenance and repair activities, providing a clear understanding of the tunnel’s condition and performance.

BIM can be integrated with asset management systems to facilitate proactive maintenance and optimize the lifecycle of the tunnel. Predictive maintenance strategies, informed by data from the BIM model and real-time monitoring, can be implemented to identify and address potential issues before they become critical. This approach not only enhances the safety and reliability of the tunnel but also reduces maintenance costs and extends the tunnel’s lifespan.

Additionally, BIM supports the operation of tunnels by providing a detailed and accurate representation of the tunnel environment. This information can be used to optimize traffic management, ventilation systems, and emergency response plans, ensuring the efficient and safe operation of the tunnel.

Future Developments and Innovations

The future of BIM in tunneling projects holds exciting possibilities, driven by advancements in technology and the increasing adoption of digital practices in the AEC industry. One such development is the integration of BIM with Geographic Information Systems (GIS), which provides a more comprehensive understanding of the spatial context and environmental impact of tunneling projects. This integration enhances planning and decision-making, particularly in complex urban environments.

Another promising innovation is the use of artificial intelligence (AI) and machine learning in conjunction with BIM. These technologies can analyze vast amounts of data, identifying patterns and trends that can inform design, construction, and maintenance practices. AI-driven predictive analytics can enhance risk management and optimize project performance, further improving the efficiency and safety of tunneling projects.

The rise of the Internet of Things (IoT) and smart sensors also presents new opportunities for BIM in tunneling. Real-time data from sensors embedded in the tunnel infrastructure can be integrated with the BIM model, providing continuous monitoring and analysis of the tunnel’s condition. This real-time feedback loop enables more proactive and responsive maintenance and operation strategies, enhancing the overall performance and longevity of the tunnel.

Conclusion:

BIM’s applications in tunneling projects are transformative, offering significant benefits in design accuracy, collaboration, project management, risk mitigation, and maintenance. As technology continues to evolve, the potential for BIM to further enhance the efficiency, safety, and sustainability of tunneling projects will only grow. By embracing BIM experts and their associated innovations, the tunneling industry can achieve new levels of performance and success, ensuring that these critical infrastructure projects meet the demands of the future.